Battery energy storage systems (BESS) face critical safety challenges in managing thermal runaway events while maintaining optimal performance. Traditional thermal barriers may stop working well during thermal runaway, when both temperature and pressure get very high. This white paper looks at how a new technology from W. L. Gore & Associates, Inc. (Gore), known as GORE Battery Insulation (GBI), creates a mechanically stable thermal barrier that maintains excellent protective properties even under severe compression and temperatures, leading to safer, higher-density BESS.

GORE Battery Insulation

Lab testing shows that GBI maintains high thermal resistance during simulated thermal runaway events, resulting in lower temperatures for adjacent cells, and a safer overall structure. Real-world testing by Our Next Energy, Inc. (ONE), found that GBI prevents thermal propagation in battery modules “at practical thicknesses and costs” (Mitigating the risk of thermal runaway propagation with GORE Battery Insulation Technology). The stability and consistency of GBI against creep, even at high temperatures, allows cell-to-pack structures. This lets designers create high-energy-density BESS containers without compromising safety.

The challenge of thermal runaway in prismatic lithium-ion BESS

Engineers deploy thermal insulation materials in BESS systems between individual lithium-ion cells to serve two purposes:

- Prevent thermal propagation during runaway events

- provide mechanical compliance during normal charge cycling

Thermal barrier materials between cells limit the spread of heat during a thermal runaway event and improve UL9540A test outcomes. The physical requirements for these barriers are severe: During thermal runaway, lithium-ion cells expand significantly due to rapid gas generation and internal pressure buildup as temperatures reach or exceed 500°C. Designers can’t predict how thermal barriers will work in a real-world environment just by observing normal operational temperatures and pressures. Instead, design and testing must consider the extreme and uncontrolled conditions that could arise during runaway events.

Modules and packs must accommodate cell thickness changes during regular operation: As lithium ions intercalate and de-intercalate from electrode materials, cell volume can fluctuate between 2% and 5%. This creates cyclic mechanical strain, which needs compliant layers between cells to maintain pressure distribution and prevent mechanical damage to components.

There’s only one space available between cells. So manufacturers now use a dual-purpose design for the interposing layers, relying on thermal barrier materials to perform both functions. This causes a basic design problem: engineers need materials that are not too stiff for battery cycling, but also not too compressible to protect against heat. Since they can’t tune these properties independently, system architects have limited options to design modules and packs for high pressure. These constraints compromise energy density, increase testing requirements, and create overly conservative designs to ensure safety.

GORE Battery Insulation: A low-compression, high-performance thermal barrier

During a thermal runaway event, local temperatures may rapidly exceed 500°C, expanding the liquids and gases within the cell and increasing pressure on the thermal barrier material tenfold (from about 0.1 MPa to 1 MPa). If the thermal barrier is compliant, it thins and loses thermal resistance, as the formula below describes.

Testing thermal barrier performance at atmospheric pressure and room temperature may yield results that differ from those under critical conditions.

GORE Battery Insulation is a non-fluorinated, flexible, bondable, low-particulating thermal barrier material. While still in development, it promises exceptionally low thermal conductivity at high temperature (around 0.05 W/m-K at 500°C), ideal for lithium-ion battery applications. GBI stays strong even under pressure and high heat. It offers a paradigm shift in BESS thermal management, providing stable barrier properties throughout cycle life, as well as during a thermal runaway event.

The stress-strain curve in the figure below shows the vast difference between GBI (green curve) and conventional aerogels (blue and orange curves). Aerogel can get much thinner under pressure (it may compress by as much as 60%), but GBI thins by less than 5% under the same conditions.

Because GORE Battery Insulation maintains thickness at high pressures, it provides high practical thermal resistance as batteries expand over their cycle life. GBI remains robust under pressure even in cell-to-pack (CTP) architectures, where long runs of cells create high compression after expansion. CTP can increase system volumetric energy density by 10% to 25% compared to cell-to-module-to-pack designs, provided engineers maintain thermal protection for cells at these high stresses. GBI keeps batteries safe even when used in thinner layers than aerogel.

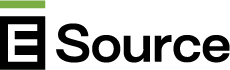

GBI retains its mechanical properties and thermal resistance even at the high temperatures that occur during thermal runaway. The data in the figure below shows Gore’s comprehensive simulated thermal runaway testing, which compared 2mm-thick layers of GBI and aerogel. The testing apparatus pressed an 800°C stainless steel mass against insulation (GBI or aerogel) under discrete variable pressure, measuring the resulting temperature at an adjacent mass:

- GBI maintains protective properties throughout the thermal event, with low (<150°C) adjacent-cell temperatures under all compressive loads.

- The thermal barrier performance for aerogels degrades dramatically under high pressure.

- With GBI, thermal performance is stable (<7°C difference) across the entire pressure range.

GORE Battery Insulation protects adjacent cells (green) from thermal runaway

Protection in high-density BESS installations

GORE Battery Insulation’s dimensional stability enables the separation of thermal protection and mechanical compliance functions. This architectural change allows engineers to:

- Select ideal compliant materials for cell-cycling requirements.

- Ensure consistent thermal protection through dimensionally stable layers.

- Simplify thermal modeling with fixed resistance values, rather than designing for variable resistances under multiple pressure conditions.

- Reduce validation complexity and accelerate design cycles.

- Optimize module and pack architecture to tolerate high pressures as cells expand over their cycle life.

The low compressibility of GBI ensures thermal barriers remain robust regardless of local variations that occur as the solid electrolyte interphase layer builds up over cycling and protects cells in actual thermal runaway events. These improvements provide confidence that thermal barrier performance will remain reliable under any future cell conditions.

Gore’s technology affords high-quality, consistent thermal barrier performance even at thicknesses below traditional options such as aerogel or cork. GBI layers have been manufactured with <0.1 mm variability in thickness, down to just 1 mm. This thin range is particularly valuable for insulating smaller-format cells, including those used in residential storage systems.

The trend in industry is to increase container energy density, installing larger cells packed more tightly into modules. For these high-energy cells, GBI is typically applied at around 2 mm, providing a meaningful advantage over conventional barriers that require 3–5 mm. This thinner profile frees up volume for additional active material without compromising safety. Further, GBI’s high mechanical stability and excellent barrier performance at high temperature and pressure will allow the architects of battery container systems to accommodate the next generation of larger cells, which provide more fuel—and therefore more heat—during runaway. GBI is easy to use and stable, which can help companies launch new batteries faster and get better insurance rates.

Real-world validation: Our Next Energy case study

ONE selected Gore’s insulation technology after evaluating traditional aerogels, silicone foams, phase-change materials, and cork. Instead of placing insulation between every cell, ONE applies it strategically, breaking thermal conduction paths at key intervals to prevent cascading failures while minimizing material usage. At the remaining uninsulated interfaces, ONE uses low-cost, compliant pads optimized solely for mechanical performance.

By adopting this approach, ONE:

- Reduces material costs through increased ratio of compliant pads to thermal barriers

- Maintains full thermal protection

- Simplifies design and validation

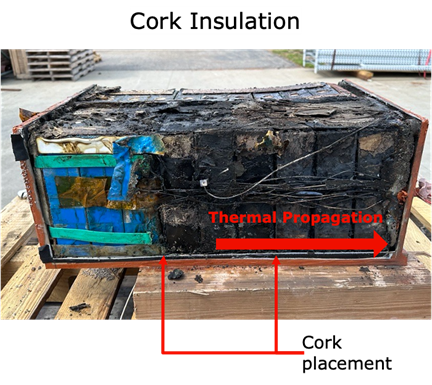

Testing results were definitive. Temperature monitoring showed that when engineers protected adjacent cells with 50% thicker cork, temperatures exceeded 500°C, while insulating cells with GBI kept temperatures below 150°C—well under the thermal runaway threshold.

The results are promising:

- Cork configuration. Thermal propagation across the module.

- GORE Battery Insulation configuration. Thermal events affected only the initiated and adjacent cells. The GBI barrier fully contained propagation and prevented it from spreading through the rest of the module.

Reducing the risk

GORE Battery Insulation’s mechanical stability ensures a module’s designed thermal protection remains effective throughout product lifecycle, and during catastrophic events.

Technical benefits

- Predictable safety margins

- Long-term reliability through compression fatigue resistance

- Worst-case protection under extreme conditions

- Enablement of cell-to-pack and other high-pressure architectures, which create margin for a 10% to 25% increase in container energy density

- Enhanced safety brings the potential to increase site-level energy density

Economic advantages

- Reduce material usage through strategic placement of GBI

- Accelerate design and validation cycles

- Enhance protection of entire BESS investment

GORE Battery Insulation solves problems with older materials by staying the same size in tough conditions and letting engineers handle heat protection and flexibility separately.

The advantages are validated by comprehensive testing and industry leaders. They include:

- High thermal resistance under extreme stress conditions (relative to alternative materials)

- Dimensional stability ensuring consistent protection

- Proven thermal propagation prevention in real-world configurations

- Design flexibility through functional separation

- Container level energy gains through a switch to cell-to-pack architectures

As the energy storage industry grows, Gore’s developmental battery insulation material provides the technical foundation for safer, more reliable, and cost-effective battery systems powering sustainable energy infrastructure.